International Packaging Films Limited.

IPAK – BROAD ABSORPTION CHILLER CASE

International Packaging Films Limited. (IPAK) is a green field project started operations in 2017 in Lahore, Pakistan. Company with a capacity of 40,000 tons per annum is in the business of manufacturing BOPP films of various grades and thickness ranging 10 to 50 microns.

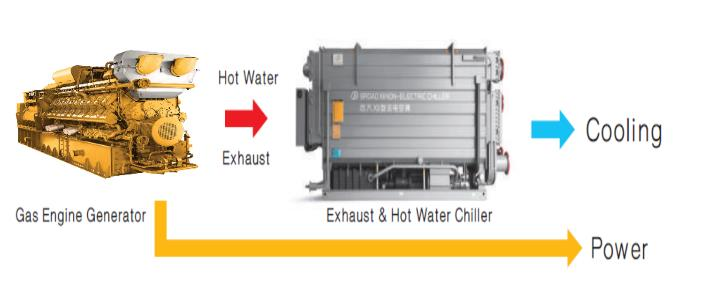

BROAD has supplied a Multi-Energy (Exhaust + Hot Water) which operates against the exhaust and jacket water of CG170 engine. Hence, all the waste heat from engine is now being utilized to produce cooling which is necessary for the manufacturing process at International Packages.

International Packages is a BOPP films manufacturing organization. The process requires stretching of particles so that films can be produced. Therefore, the resultant heated product needs instant cooling to set in shape. At IPAK, chilled water from BROAD multi-energy absorption chiller is utilized to fulfill the aforementioned requirement.

- Total capacity = 660 USRT

- Chiller with TITANIUM TUBES. Increased lifespan of 60 years.

- Horizontal Fire Tube HTG structure. Easy maintenance, low

crystallization risk & easy soot cleaning. - Real time online COP displayed on the chiller screen. Instant, Hourly

and Daily COP indication. Maximum number of parameters on

screen. - All chillers are being monitored at BROAD Global Monitoring Center

for free throughout chiller life span. Three tier monitoring. - Free of cost solution sampling service throughout chiller lifespan.

- Only BROAD can perform FAT on exhaust chillers.

- With waste heat recovery chillers, BROAD makes huge annual

savings when compared with electric chillers. (PKR 35 Million approx.)