Al Karam Textile Mills

ALKARAM TEXTILE. (NOORIABAD)

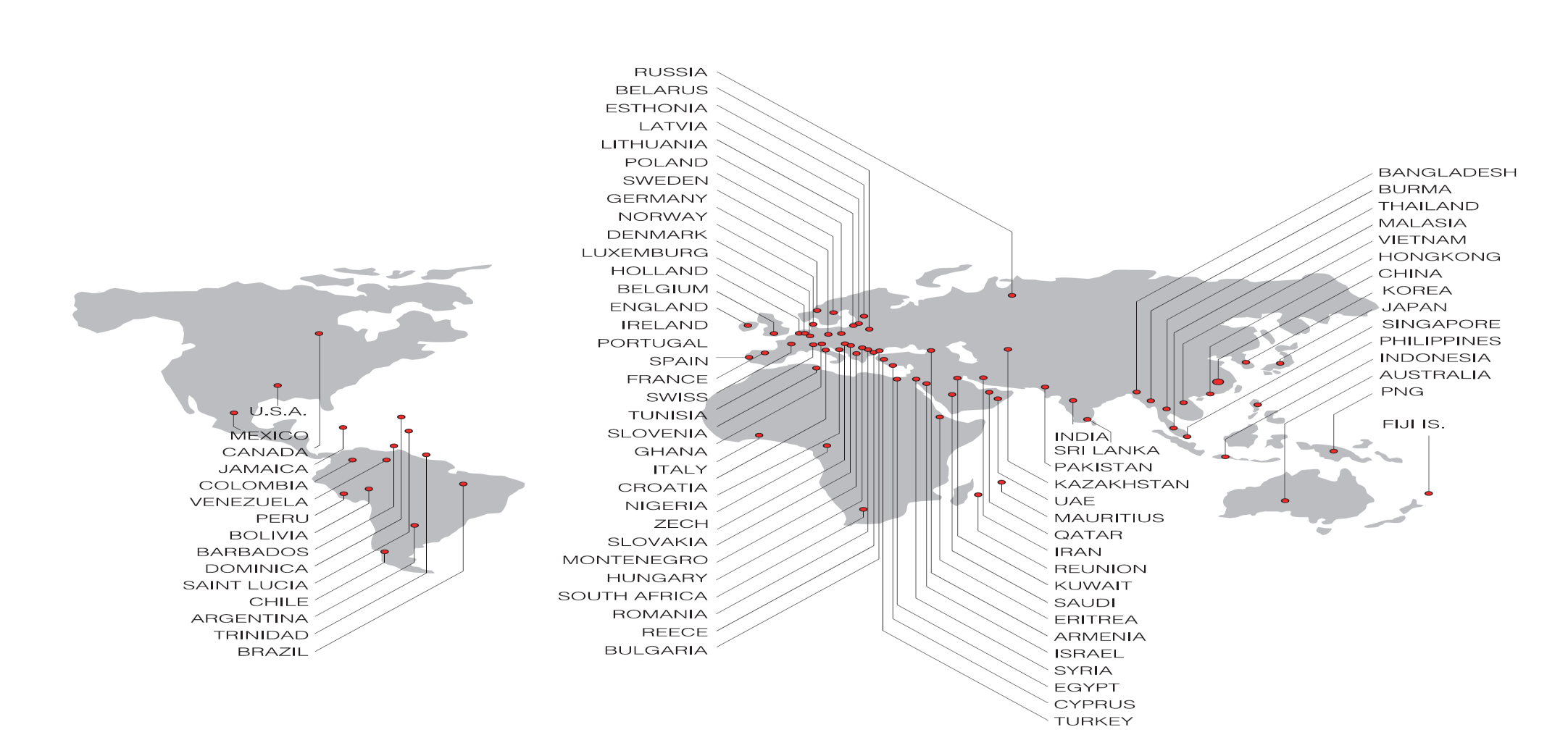

Broad Chiller are used in different processing facilities around the world to maintain process temperature, improve

quality, reduce static and provide air cooling. Some of the World’s leading manufacturers put their trust in Broad Air

Conditioning systems to help them achieve their production objectives.

The company has been serving the global textile industry for more than 30 years and is highly experienced in many different

HVAC related technologies, Chillers Water distribution system, Air Quality products etc. Chiller systems are designed for each individual

application, textile experts to create the optimal production environment. If required, Broad regional R&D departments can work with a

production team to deliver innovative solutions for unique textile processes. Broad A/C engineering teams offer installation,

commissioning and maintenance support to ensure improved production efficiencies continue to return on the initial investment for

many years.

ALKARAM TEXTILE Mills was setup to provide innovative textile solutions across the globe for more than 35 years. It is the

largest vertically integrated textile setup in Pakistan. It is one of Pakistan’s largest consumers of Organic Cotton & Better Cotton

Initiative (BCI) cotton.

Maintaining the correct temperature & relative humidity will prevent moisture loss during a textile’s processing and storage. Typically, losses can be reduced from 4% to just 0.5%, which results in an immediate 3.5% increase in product yield and profitability.

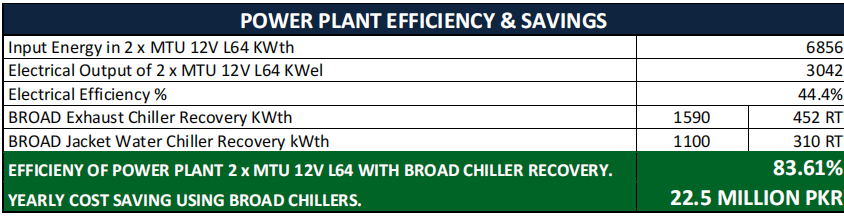

Broad offers 2 x Chillers, On waste Heat of 1.5 MW x 2 Engines of MTU 12V L64. Duplex Exhaust & Jacket Water Chiller of Capacity 450 & 310 =760 RT in Total. Save carbon footprint of 13 million Kg/Annum i.e., equivalent to 0.71 million Trees/Annum.

ALKARAM textile was a user of Numerous Brands of Chillers but They Choose Broad for their new factory in Nooriabad Over other Brands because of our product Reliability, Efficiency and Strong backup Support.

Optimal condition reduces yarn breakages in weaving, reducing machine downtime as well as loom stop marks and weavers’ knotsin the finished product. Broad has helped manufacturers increase their production efficienciesfromaslow as 49% up to 96% through effective Environment condition control.

Broad Chillers can deliver around 5°C of evaporative cooling to a textile production facility. The increased humidity will also suppress dust, fly and lint creating a healthier and more productive atmosphere for employees.

IMPROVING PLANT EFFICIENCIES WITH BROAD

Using waste heat from power generation or industrial process as the energy source to realize free cooling,

Industrial waste heat, exhaust and hot water from power generation are 100% green energies and can be treasure instead of waste.

Broad has a comprehensive range of products to suit any processing facility. Utilizing waste Heat sources, helps to achieve

the Optimal temperature and humidity that is feasible for the plant operation.

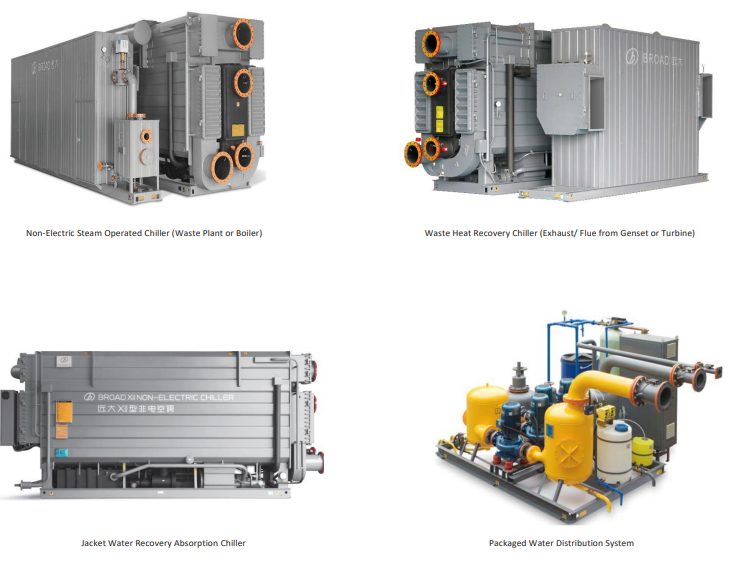

Broad product such as Absorption (Non-Electric) Chillers, Waste Heat recovery Chiller, Power Efficient Oil Free Chillers,

Packaged Water Distribution System, Air purification & Quality devices.