Through summer, the electric load increases due to high electricity consumption caused by high cooling demand. The electrical crisis that many countries are facing turns out to be more critical in summer which encourages the need to find alternative ways for cooling, since most buildings are air-conditioned using mechanical vapor compression air- conditioning systems. These traditional systems are known for their high energy consumption. Moreover, they use chlorinated fluorocarbon compounds, which lead to the depletion of the ozone layer that eventually leads to global warming. Given the fact that solar energy is obtainable worldwide and produces electrical and thermal energy [3], and the fact that the maximum available solar power and the peak cooling load happen at once, combining solar energy with the cooling system may be a solution for the energy consumption problem [4] as well as environmental problems, since solar cooling is an environmental-friendly substitute for conventional cooling

The technology of providing cooling from Solar is invented by BROAD from scratch, which counters to the common sense. Because we’ve processed the second law of thermodynamics: with each energy conversion, there is always energy loss. We understand electric air cons require five energy conversions to produce the cool air.

They are fuel→ thermal energy → mechanical energy → electric energy → mechanical energy → cold air.

While BROAD directly provides cooling in one energy conversion, the energy efficiency is undoubtedly doubled. What’s more, the separate heating technology invented by BROAD combines cooling, heating and hot water in one chiller.

The hot water heated by the solar thermal energy through solar collectors is supplied to the solar absorption chiller-heater.

his input heat energy from Solar heats LiBr solution and generate vapor, which is then condensed into water by cooling water. When the refrigerant water enters evaporator (in high vacuum condition), its temperature goes down immediately to 5℃. And it is sprayed over the evaporator tubes, and chilled water from 14℃ drop down to 7℃ to make cooling.

The refrigerant water absorbs heat from air conditioning system and evaporates, then is absorbed by concentrated LiBr solution from the generators. The cooling water takes away the heat and rejects it into the air. Diluted solution is pumped into HTG and LTG separately to be heated to begin the process all over again.

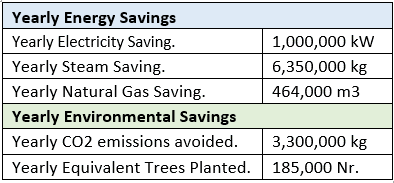

The common operational period for absorption chiller in Pakistan is eight months through the year. These eight months also include two months of monsoon season. When analyzed the operational costs of chillers over a course of aforementioned eight months, Solar Chillers were found to be cost efficient and environmental friendly. This is depicted in the data below:

Air Conditioning Expert: BROAD service engineers provide excellent maintenance to air conditioning equipment to make sure the equipment runs at high efficiency in long term.

Air Conditioning Housekeeper: BROAD operation technicians conduct fine operation and management to make sure the air conditioning performance can meet customers’ requirement.

Cover the cost: Cover the cost according to the contract, including equipment energy efficient retrofitting, air conditioning energy, equipment maintenance, and water quality management etc.

K.B Trade Centre, Plot 8 Main University Rd, W.C.H.S Block 4 Gulistan-e-Johar, Karachi, 75290.